POSITION:HOME>Company news

How to know the pros and cons of industrial aluminum profile

CLICK:94TIME::2021-07-12 10:25

Now there are more and more enterprises, not to mention industrial aluminum processing manufacturers, there are always some industry standards, the requirements of industrial aluminum profile is different, so we can do some comparison on the quality of industrial aluminum profile! What are the ways we can judge the quality of industrial aluminum profiles? How can I buy good quality industrial aluminum profiles?

Industrial aluminum profile is a kind of aluminum as the main component of alloy material, aluminum rod through hot melting, extrusion to get different shape of the cross section of aluminum material, but the proportion of the added alloy is different, the production of industrial aluminum profile mechanical properties and application fields are also different.

1, aluminum profile manufacturers - large aluminum profile factory, raw materials, production technology standards, strict quality control, processing costs than small manufacturers more high, processing costs can be 2000-3000/ ton difference. Reduce by 2-3 yuan/kg. In recent years, with the level of industry, the aluminum industry is becoming more and more popular. Sales also presented diversification, price disparity. Unknown customers will only choose industrial aluminum sales companies from the lowest price. This has forced some companies that insist on quality first from lower raw material and processing costs to ensure sales, and the market chaos has become increasingly obvious.

2, a chemical composition, mixed with a lot of waste aluminum, industrial aluminum profile can greatly reduce the cost, but will lead to industrial aluminum chemical composition is not qualified, seriously endanger the safety project.

3, thickness distribution of roughly the same size drawings, as well as section size, width, center hole, but the difference in wall thickness is very large, can also be quite different weight, each price is also corresponding to a large gap. In addition, lower industrial aluminum can reduce some shutdown times, reduce chemical reagent consumption, lower cost, but the material corrosion resistance is greatly reduced.

4, oxide film thickness - the thickness is not enough, aluminum surface is easy to rust and corrosion. The national standard for construction and industrial aluminum oxide film thickness should not be less than 10um(micron). Some properties name, address, production license, certificate of industrial aluminum profiles, film thickness is 2 to 4um. According to expert estimates, each reduction of 1um oxide film thickness, can reduce power consumption per ton of material more than 150.

Ranking

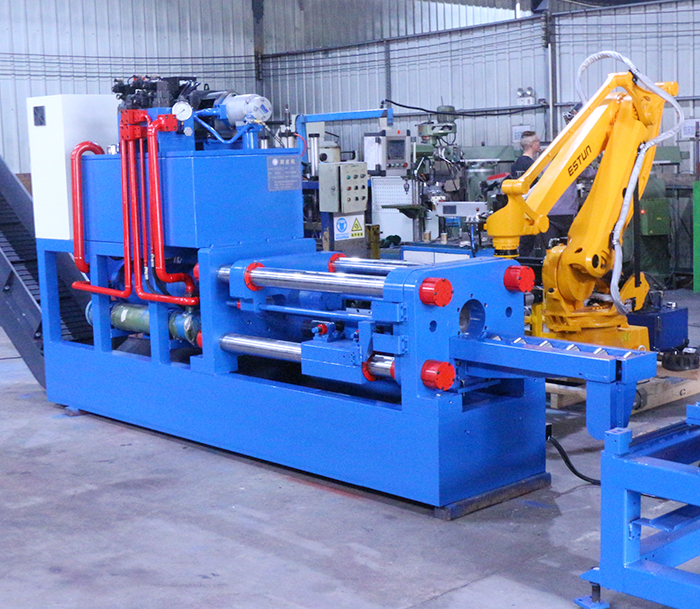

- Aluminum profile automation equipment in the production proc

- How to know the pros and cons of industrial aluminum profile

- Aluminum profiles should be cooled to a certain temperature

- What is a precision automatic saw?

- Aluminum profile automation equipment factory to remind you

WeChat

WeChat